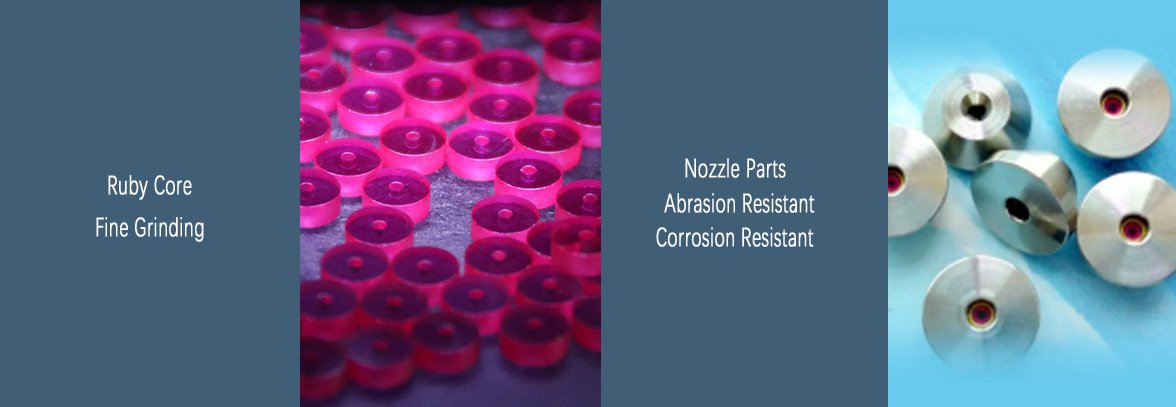

The Mohs hardness of ruby is 9. Ruby refers to corundum with a red color. The main component is alumina. Ruby is hard and wear-resistant. It is used in the manufacture of jewelry rings in the civil field, and it is mainly used in the manufacture of bearings that require special wear resistance in the industrial field. Jet nozzles, high-pressure road sign cleaning equipment nozzles, artificial fog nozzles, 3D printer nozzles, etc.

Ruby Nozzle Features

1. The ruby nozzle has a high edge finish, high pressure resistance and wear resistance

Changyuan uses high-precision equipment to grind the ruby nozzle hole to ensure that the inner hole finish of the ruby nozzle reaches above 0.2, the edge finish is high, high pressure resistance, and wear resistance

2. Ruby nozzle has high hardness and high temperature resistance

Changyuan Spray Technology selects high-quality ruby blanks for nozzle manufacturing, and the selected ruby has a Mohs hardness of 9 or more

3. Ruby nozzle is more resistant to corrosion, rust and oxidation

The red color of ruby comes from chromium (Cr), mainly Cr2O3, the content is generally between 0.1-3%, up to 4%. Anti-corrosion, anti-rust, anti-oxidation, can improve the hardness and strength of the material, used for important metal components such as stainless steel manufacturing, auto parts, tools, etc.