Introduction to the composition of CYCO dry fog dust suppression system

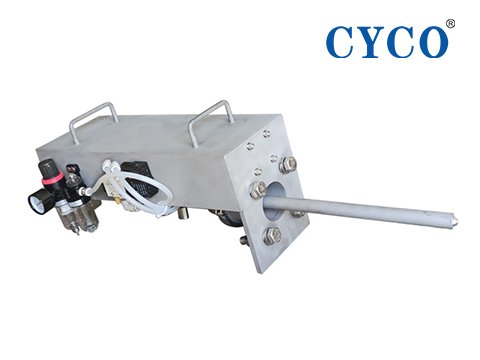

1. Soda dispenser: The whole body is made of stainless steel 304 shell, including stainless steel pipe fittings, water and air path pressure regulating valves, water and air path manual ball valves, used with universal joints, to ensure the balance of water and air pressure in the nozzle, and to ensure the spray effect. Add electromagnetic valves, remotely control the water and gas circuit switch, and also increase the function of antifreeze heat preservation and heat tracing

2. Ultrasonic dry fog nozzle: The whole body and the tripod supporting the vibrating head are made of stainless steel 316. The nozzle assembly is easy to disassemble and easy to maintain. After the water droplets are atomized, the particles are small and uniform, and the dust suppression effect is good

3. The host has different configuration parameters and models for selection

4. Spray box: The box body is made of 304 stainless steel, which is impact-resistant and corrosion-resistant. The water and gas dual-fluid design is beneficial to improve the atomization effect and increase the antifreeze heat preservation and heat tracing function. It is suitable for different environments. A single spray box can be installed with 2-9 dry Mist nozzle, anti-drip

The base of the stainless steel nozzle can be disassembled repeatedly without slipping the wire, and the installation feet are included with the machine, which can adjust the angle of 360°

5. The universal joint assembly includes water and air pipe joints, nylon protective cover, fastening cover, aluminum alloy ball seat, and ball cover. After installation, the spray direction can be adjusted within a certain angle range on the spherical surface, and heating can be installed in the aluminum alloy ball seat. Rod, antifreeze in winter, has the characteristics of simple structure, convenient installation and adjustment, etc.

Application

It is suitable for dust control in crushing, transfer, stacking and reclaiming of industries such as cement, chemical industry, steel, and coal mines. It is mainly aimed at the treatment of dust pollution particles with a diameter of 1-100 μm, and the dust reduction efficiency reaches 95%.