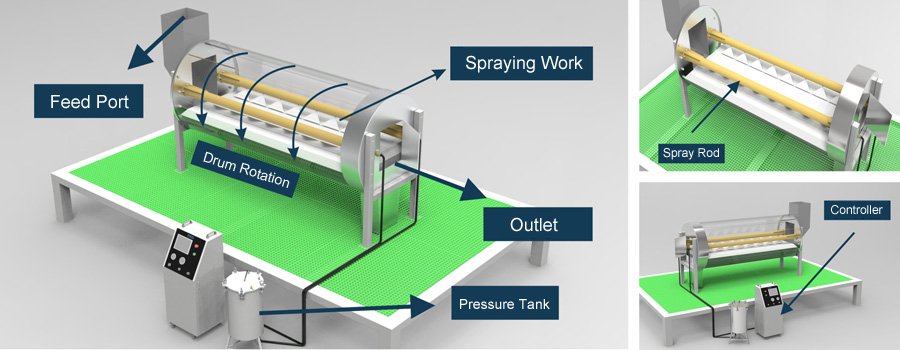

Overview

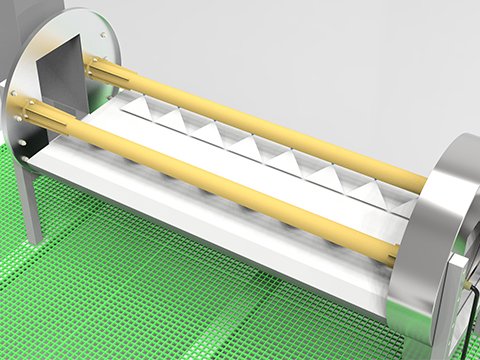

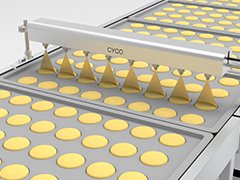

Precise spray control ensures consistent, uniform liquid application with minimal waste even with variations in tonnage or line speed.

Because the pressure remains constant, the integrity and coverage of the spray remains consistent.

The use of hydraulic nozzles for spray humidification eliminates the need for expensive compressed air and minimizes the problems of misting and overspray from air atomizing nozzles.

The system controls the flow with rapid on and off cycles so fast that the flow appears to be almost constant.

Traditional nozzle flow adjustments require changes in pressure, which also changes nozzle angle/coverage and droplet size.

Precise spray control keeps the pressure constant and the flow rate changes without changing the spray performance.